- Wide range of applicable working condition,high temperature and high pressure resistance. applicable

to super low temperature and vacuum condition. chemical resistant gasket is available under various

medium,through change of composition of gasket.

- Strong strees compensation. stable and reliable sealing performance even under frequent pressure

fluctuation condition .

- Perfect sealing performance.

- Normal requirment of flange surface finishing which contact with gasket.

- Easy installation and low pre-tightening stress of gasket.

|

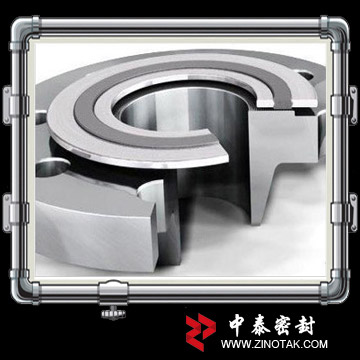

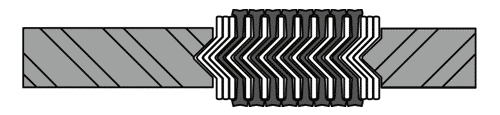

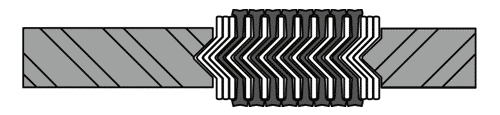

ZT-G401R Basic Type

Basic construction type, inner and outer diameters are reinforced

with several piles of metal without filler to give greater stability

and better compression characteristics. - Suitable for tongue and

groove, male and female or grooved to flat face flange assemblies. |

|

|

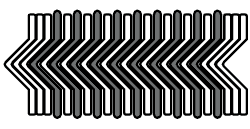

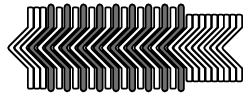

ZT-G401IR Inner Ring Type

Solid inner metal ring acts as a compression stopper. To prevent

accumulation of solids, reduce turbulent flow of process fluids

and minimize erosion, damages of gasket between flange bore and

the inside diameter, the annular space is filled up by solid inner

metal ring. - Suitable for male and female pipe flanges. |

|

|

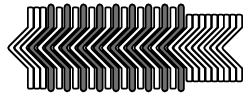

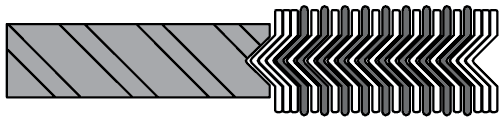

ZT-G401OR Outer Ring Type

Solid outer ring accurately locates the gasket on the flange face

to give the additional radial strength to prevent the gasket blowout

and acts as a compression limiter. In case of installing the outer

ring, it is very easy to install the gasket to flange face because

the end of outer ring will touch at bolts - Suitable for use with

flat face and raised face flanges. For class 900 and above an

internal ring is recommended. |

|

|

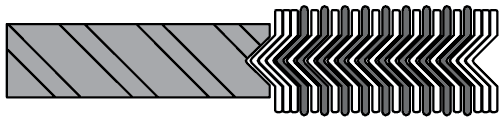

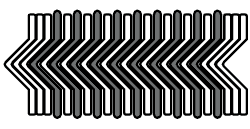

ZT-G401IRO Inner & Outer Rings Type

A inner ring and outer ring type gasket will give an additional

compression limiting stopper for gasket inner and outer side. It

will prevent the corrosions on flange face at annular space. -

Suitable for use with flat face and raised face flanges and

specified for high pressure / temperature service - Class 900

and above or where corrosive or toxic media are present.

|

| |

Do you want to know more about Zinotak?

Do you want to know more about Zinotak?